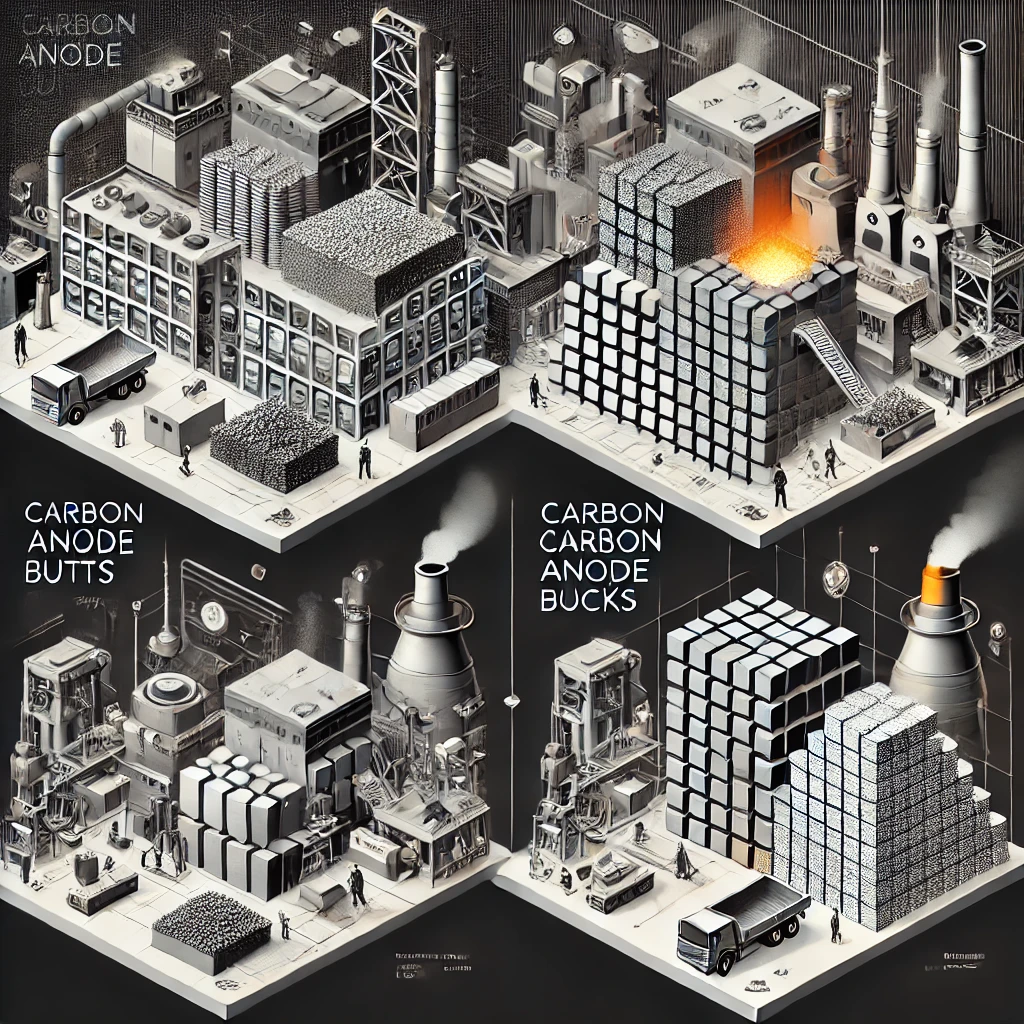

Carbon Anode Butts vs. Blocks: Differences and Applications

Carbon anodes play a critical role in the aluminum smelting process, with their byproducts and components being integral to industrial operations. Two commonly discussed elements of this process are carbon anode butts and carbon anode blocks. While they are closely related, these materials differ in composition, production, and applications. This blog explores the differences between carbon anode butts and blocks, highlighting their roles, characteristics, and industrial uses.

What Are Carbon Anode Butts?

Carbon anode butts are the remnants of carbon anodes that are left after their partial consumption during the aluminum smelting process in electrolytic cells. Although the majority of the carbon anode is consumed during the Hall-Héroult process to produce aluminum, the remaining butts retain valuable carbon content.

Key Characteristics of Carbon Anode Butts

- Size and Shape: Irregular pieces varying in size, depending on the extent of consumption during smelting.

- Carbon Content: Contains a high percentage of residual carbon.

- Impurities: Often contains residues such as cryolite, alumina, and other electrolytic bath materials.

Applications of Carbon Anode Butts

- Recycling into New Anodes:

- Cleaned and processed butts are blended with fresh raw materials to produce new carbon anodes.

- Fuel Source:

- High calorific value makes them suitable as an alternative fuel in cement kilns and power plants.

- Metallurgical Uses:

- Used as a carbon source in steelmaking and other metal refining processes.

What Are Carbon Anode Blocks?

Carbon anode blocks are manufactured components made from calcined petroleum coke and coal tar pitch, designed specifically for use in the aluminum smelting process. These blocks are consumed during electrolysis as they react with oxygen to produce carbon dioxide.

Key Characteristics of Carbon Anode Blocks

- Size and Shape: Uniformly shaped, large blocks designed for easy handling and precise installation in electrolytic cells.

- Carbon Content: High-purity carbon with minimal impurities.

- Thermal and Electrical Properties: Excellent thermal stability and electrical conductivity, essential for smelting operations.

Applications of Carbon Anode Blocks

- Primary Aluminum Production:

- Used as electrodes in the Hall-Héroult process for producing aluminum.

- Steel and Metallurgical Industries:

- Serve as a carbon source in certain refining processes.

- Recycling:

- Spent anodes are recycled into new blocks, contributing to a circular economy.

Key Differences Between Carbon Anode Butts and Blocks

| Aspect | Carbon Anode Butts | Carbon Anode Blocks |

|---|---|---|

| Origin | Residual material after anode consumption | Manufactured from raw materials |

| Shape | Irregular and varied | Uniform, rectangular or cylindrical |

| Purity | Contains impurities from smelting process | High-purity carbon material |

| Applications | Recycled, fuel source, metallurgical uses | Electrodes in aluminum smelting, recycling |

| Cost | Lower due to recycled nature | Higher due to manufacturing process |

Sustainability and Environmental Impact

Carbon Anode Butts

- Recycling: Reusing butts minimizes waste and reduces the need for fresh raw materials.

- Environmental Concerns: Proper cleaning is required to remove hazardous residues before reuse.

Carbon Anode Blocks

- Sustainability: Incorporating recycled materials in block production reduces environmental impact.

- Energy Consumption: The manufacturing process is energy-intensive but essential for high-quality anodes.

Challenges in Handling and Processing

Carbon Anode Butts

- Impurity Removal:

- Residues such as cryolite and alumina must be removed before reuse.

- Logistics:

- Transporting irregular butts can be inefficient without proper equipment.

Carbon Anode Blocks

- Production Costs:

- Manufacturing requires precise conditions and high-quality raw materials.

- Consumption in Smelting:

- Blocks are gradually consumed, necessitating constant replenishment.

Future Trends

- Innovations in Recycling:

- Advanced methods to process anode butts more efficiently for reuse.

- Sustainable Manufacturing:

- Increasing use of renewable energy and recycled materials in block production.

- AI and Automation:

- Leveraging technology to optimize production and recycling processes.

Conclusion

Both carbon anode butts and blocks are essential components in aluminum smelting, each serving distinct yet complementary roles. While butts are valued for their residual carbon and recyclability, blocks are indispensable for their high conductivity and structural integrity. Understanding their differences and applications helps industries optimize their use, reduce costs, and support sustainability initiatives.

As technology and sustainability practices evolve, the efficient management and utilization of carbon anode butts and blocks will continue to play a crucial role in the future of aluminum production and other industrial processes.